The Customer

A global OEM that specializes in the manufacturing of construction, agricultural, ground maintenance, and industrial vehicle equipment.

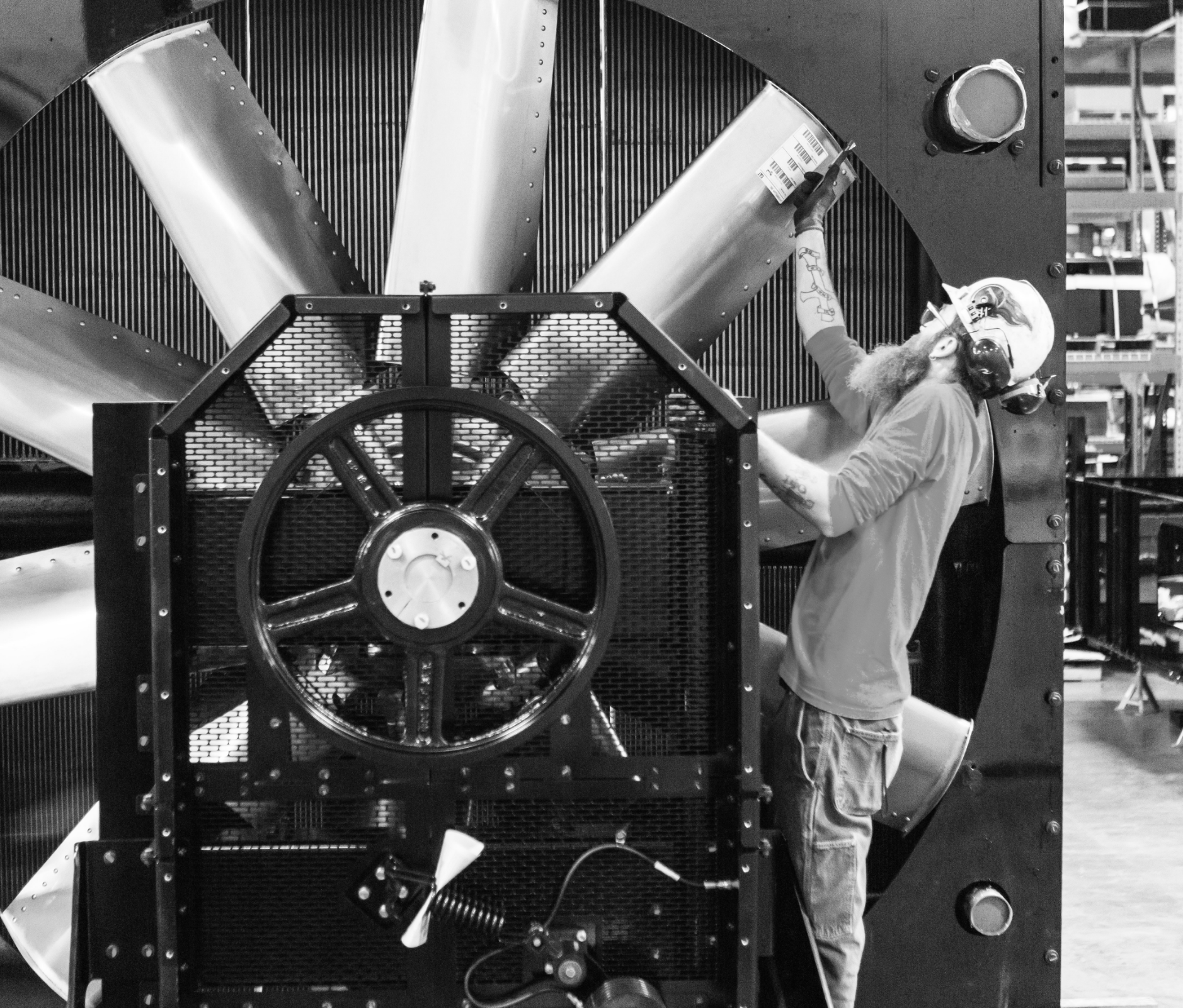

Driving Production Out: How We Stepped In

Unable to develop an error-proof assembly process to prevent part failure, the customer turned to WCI for assistance to meet a large field replacement program, as well as ongoing production needs.

Background & Situation

The customer was experiencing zero hour part failures—failures prior to arriving to customer or immediately upon first use. They needed a replacement program along with improved quality control for ongoing production.

- Fan drives failing at a high rate

- Struggled to diagnose the origin of the issue

- Lack of data creating blind spots

- Explosive demand driven by high service requirement

- Additional assembly source required to increase production capacity

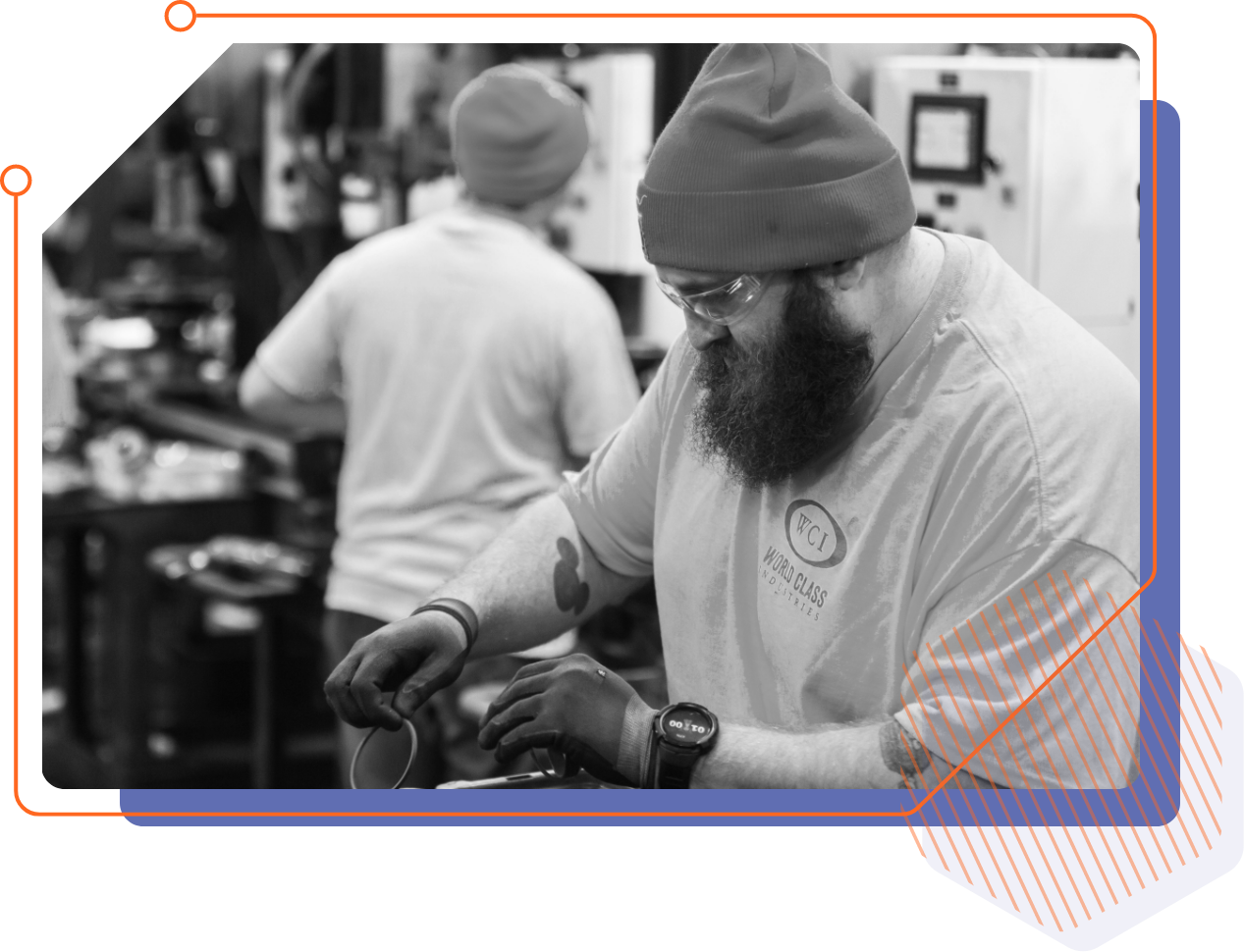

WCI Solutions

By engaging collaboratively with our customer, we were able to engineer and implement a new assembly process, solving both of the quality and capacity challenges.

- Simplified communication to single point of contact for OEM.

- Utilized in-house PLC programming capabilities with custom torque tools to ensure controlled process and quality.

- Paired state-of-the-art technology with unique, serialized barcodes for data capture of critical information regarding press force, distance, and torque.

- Integrated innovative assembly line design leveraging customer quality and engineering partnerships.

CASE STUDY RESULTS

Standout Achievements

Our team developed PLC-driven solutions that from day 1 resolved prior part failure issues and resulted in the full transition of production and service to WCI within 18 months.